Maximum results at minimum cost.

Based in Jaipur, Rajasthan, India, the company manufactures apparel for Japan and other prominent apparel companies around the world.

In recent years, our original brand Naav has been well received mainly in Australia, and we also sell half-made-to-order products all over the world.

Since InfoEye’s establishment in 2002, Choice Fashions’ planning, sewing, and export management systems have all been handled by InfoEye’s India office.

The entire system from planning management to sewing and export management has been built at the InfoEye India office.

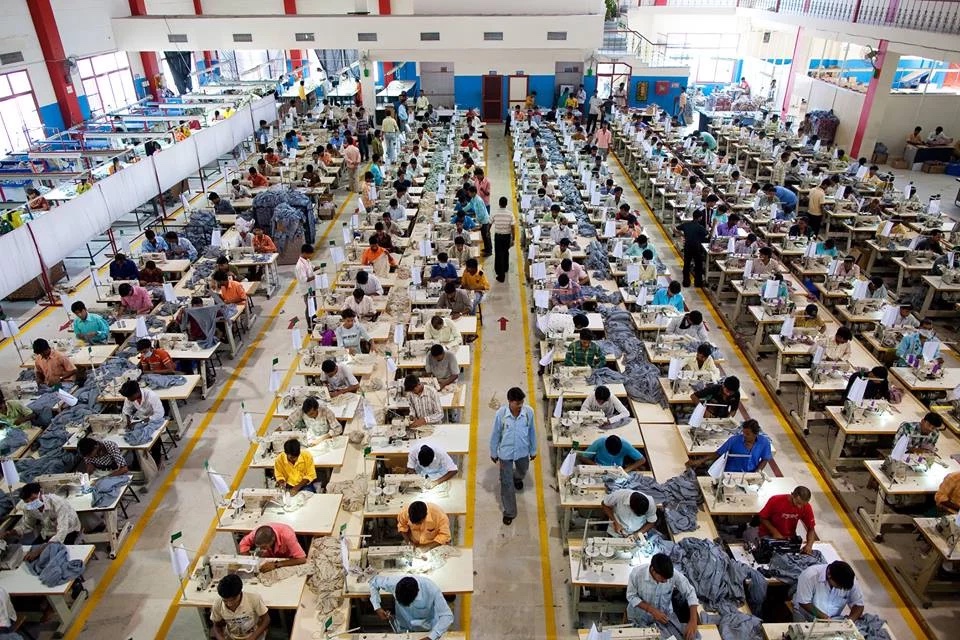

Very well maintained sewing factory in Jaipur.

Very well maintained sewing factory in Jaipur.

○ Management of raw land resources

For a sewing factory, it is very important to manage the ordering and inventory of fabric materials, but it has not been easy to manage them well due to complicated shipping and receiving, erratic meters, and production cutbacks.

Therefore, Choice Fashions began its IT reforms by systematizing fabric material order forms in collaboration with InfoEye.

Choice Fashions’ IT reforms began with the creation of a system to systematize fabric material order forms in collaboration with Info Eye.

○ Daily cutting management and line management are also systematized.

The next step was cutting management and line management.

With systemization, the benefits will be seen by all, not just those in the field. However, before the introduction of the system, we were met with fierce opposition from those onsite who were making full use of paper and Excel, which have fewer restrictions.

However, by patiently helping them understand the benefits of systemization, they gradually began to see the advantages of systemization, and after six months, they were able to realize the benefits of the system.

C.E.O. Navin Adwani (left) meeting with us via video conference

○ Realizing the benefits of centralization from fabric material management to export

The system, which has been built little by little over more than a decade, has been centralized from raw material management to product management and export management, thereby reducing labor costs.

By centralizing the system from fabric material management to product management and export management, labor costs have been reduced, all kinds of losses have been cut, and the company has realized that it has succeeded in sharing internal information.

We have realized that all kinds of losses have been reduced and that we have succeeded in sharing information within the company.

○ Exhibition orders and headquarters tally on iPad

This year we will also participate in the PURE exhibition in London, England, as the original brand Naav.

We will be exhibiting there using the InfoEye trade show tool to sell our products.

Real-time order and pickup status can be aggregated and analyzed even in India, a country far from London.