CASE STUDIES

20 cardboard boxes of proposals in your iPhone

Dear Shirley Temple.

Before APASYS was introduced, sales-related operations were mainly managed using Excel. Sales, customers, orders received and placed, etc. were managed in separate Excel files, which made data registration and form creation complicated, and even for sales analysis, we had to open multiple files and manually process the data, which meant that most of the work was analogue management.”

Linking planning, profitability and production

Dear Intertextured.

Conventional planning and management methods are highly dependent on the individual. The system makes it easier and more efficient to manage client submissions and images.

From fabric product management to the preparation of sales literature.

Dear Parika.

We use Kirikom Plus from the registration of fabric information to the preparation of sales materials to be sent to customers after negotiations. We have high hopes for the web-based wholesale exhibition system, which we plan to release in the future.

Minimal cost, maximum impact

Dear Choice Fashions.

For sewing factories, it is very important to manage the ordering and stocking of fabric materials, but it has not been easy to do so due to complicated shipping and receiving, erratic metering and production cut-backs.

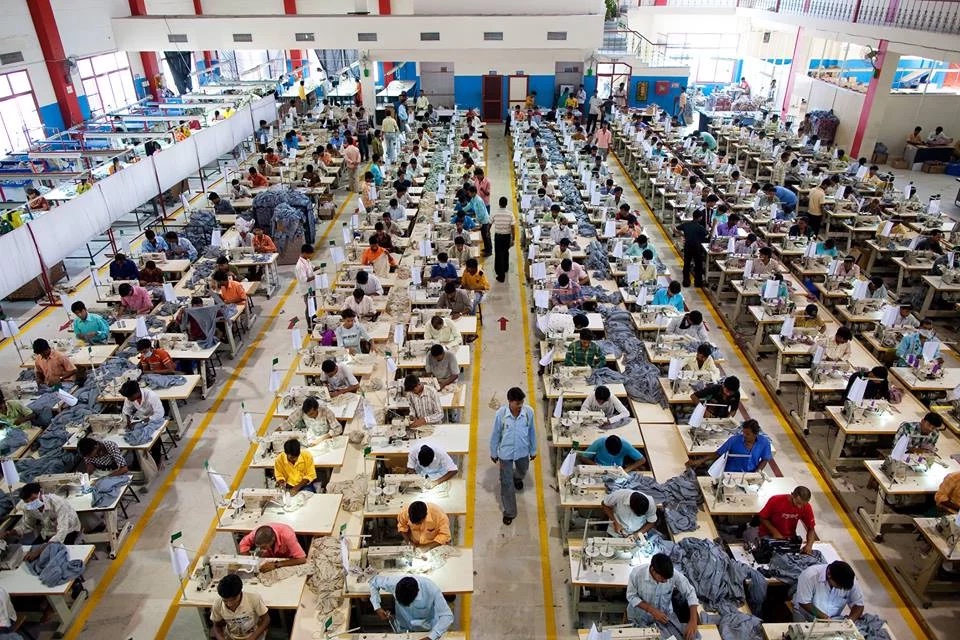

Used for daily cutting management and progress control

Dear Spring Overseas.

We have been using the InfoEye system since the foundation of InfoEye in 2002. Without this system, we would not be able to manage fabric arrangements, material arrangements, cutting management and progress management in India.